Epoxy Machine Grout

Armagrout - for maintaining alignment in vibrating machinery. Higher performance than cement grouts giving lower machine vibration. Higher tensile and compressive strength, has ultra low shrinkage as it cures, is crack resistant, and oil penetration resistant.

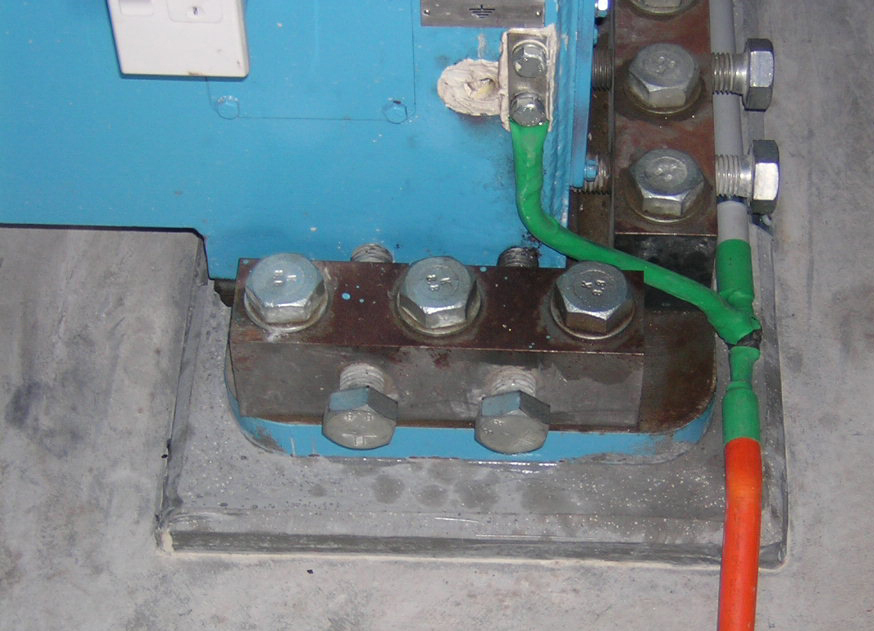

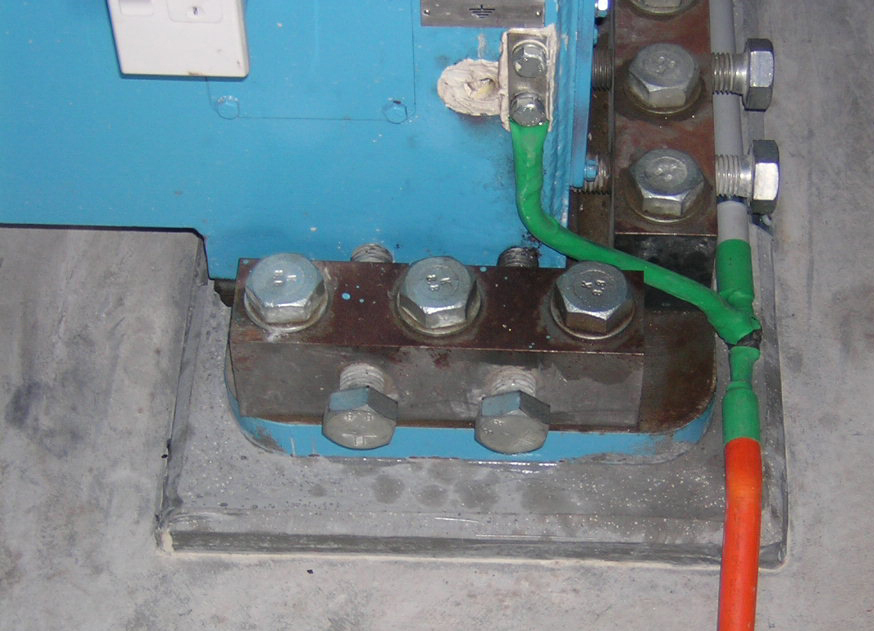

ArmaGrout epoxy and vinyl ester polymer grouts are three component silica filled polymer composites used frequently for machinery foundations. The many benefits of these polymer grouts mean they are the foundation material of choice for critical equipment where maintaining alignment is essential.

Equipment such as compressors, turbines, pumps and fans benefit from using high strength epoxy foundation grout. With equipment such as this, even the slightest misalignment can mean very expensive maintenance for bearings, crankshafts, pistons, rotors etc. And when they are at the heart of a plant or process, downtime to make repairs is very costly.

All rotating equipment has out of balance forces to some degree. The energy of these out of balance forces has to go somewhere, and is often seen as vibration or shaking of the machine itself. This of course leads to damage and costly repairs. Machinery design calls for the out of balance forces to be transmitted and absorbed in the equipment foundations. This is why the foundations for compressors etc are often very large concrete structures.

The epoxy foundation grout is the all important tie between the equipment and the foundation. The epoxy grout bonds to the equipment and the foundation, has a high tensile and compressive strength, has ultra low shrinkage as it cures, is crack resistant, and oil penetration resistant.

On the other hand cement grouts have low tensile strength, are not crack resistant, and not oil penetration resistant. The result is that under constant dynamic loads under compressors and other rotating machinery, the tie to the foundation can be compromised and lead to increasing machinery maintenance.

This is why epoxy grout is specified for critical applications. It is more costly than cement grouts, but offers key performance that the cement grouts cannot.

Key Features

- High Strength: ArmaGrout epoxy and vinyl ester polymer grouts have compressive strengths more than twice the strength of standard cement based grouts.

- Moisture Tolerant: The bond strength to damp concrete is in excess of 2 MPa with surface preparation by high pressure water blasting and grout placement soon after. ArmaGrout epoxy grouts will cure in the presence of moisture and will even cure underwater.

- Fast Installation: Fast cure allows installation to proceed quickly and the machine to be placed into service faster. Over night cure is often sufficient so pumps, fans, supports etc can be put under load sooner than if cement based grouts had been used.

- Oil and Chemical Resistant: Outstanding

- resistance to oil and chemicals ensures the foundation does not deteriorate as cement based grouts can.

- Outstanding Adhesion: The bond strength of ArmaGrout epoxy grouts to steel is in excess of 6 MPa. The bond strength to concrete exceeds the surface strength of concrete.

- Economical: The ArmaGrout aggregates are formulated to reduce costs but retain flow properties.