Designing with Tellerette Tower Packing

Design Advantages

- Higher gas absorption efficiencies resulting from the continuous gglomeration/dispersion characteristics which constantly expose fresh liquid surface area to the gas flow.

- Greater gas flow capacity permitting use of smaller diameter, lower cost columns.

- Non-plugging operation, even when appreciable particulates are present.

- No flooding.

- No channelling when proper initial liquid distribution is used.

- Tellerette® Tower Packing is the first choice for many new absorption and scrubber applications and is an ideal replacement for existing extended surface packing, especially where greater throughput and/or efficiency is desired.

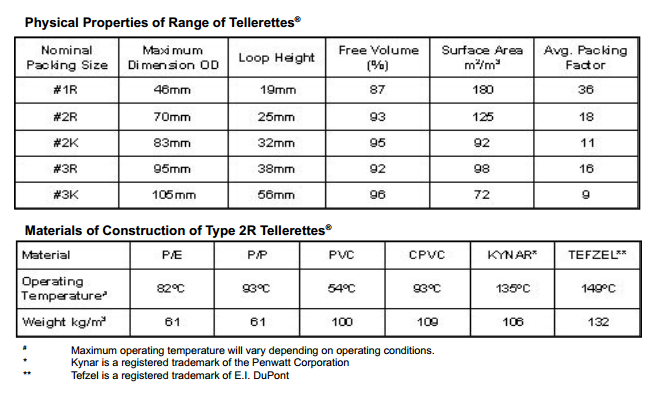

- Tellerette® Tower Packing is available in #1, #2, and #3 sizes and in many different materials of construction: #2 are moulded in New Zealand, and #1 and #3 are imported from the USA as required.

Design Tips

- Tellerette® Tower Packing maintains good liquid distribution through packing depths in excess of 10 metres. Good initial liquid distribution is essential. Spray headers using full cone spray nozzles are recommended. Weir distributors are not recommended.

- Design of the packing supports is important. The plates or grating should have an open area of 75% to 80%. Intermediate supports must be of a design that will avoid maldistribution. Plastic packing support plates available from Armatec are particularly useful in this regard.

- A rough rule-of-thumb for calculating liquid hold-up in a Tellerette® Type 2R packed bed is to multiply the volume of packing used in the tower by 5%. This will provide the volume of liquid hold-up. To obtain weight multiply by the liquid density. For more exact liquid hold-up data,

- please refer to the Tellerette® performance curve entitled “Liquid Hold-up”.

- Tellerette® Tower Packing can be operated at capacities up to the phase inversion point. Because of their open filamentous configuration, phase inversion in a Tellerette® packed column can be reversed by simply reducing either the gas or liquid flow. The tower does not have to be shut down and restarted.